14 Sep VCI – Vapor Corrosion inhibitor: A Need For Secured Packaging

What is A Vapor Corrosion Inhibitor?

VCI – Vapor Corrosion Inhibitor VCI provides anti-corrosive metal protection to address the corrosive nature of ferrous and non-ferrous metal products. A unique multi-metallic VCI concentrate for plastic and paper application. VCI is the environmentally preferred corrosion protection for metal components. VCI master batch can be blended with many polyethylene resins (LLDPE/LDPE/HDPE/PP) to form a broad range of anti-corrosion packaging systems. Kraft paper can also be used as the carrier for VCI.

Why to Use VCI?

Worldwide corrosion costs industry and manufacturing approximately US $1.8 Trillion annually. VCI protects against corrosion and other environmental variables that are directly responsible for loss due to corrosion attack.

- It provides effective corrosion protection to a wide range of metal types

- Its versatility allows it to be used in a wide range of polymer systems and many fields

- VCI films provide protection against moisture

- VCI is clean, very easy to use and handle

- VCI films allow for visual inspection of product without unwrapping

- VCI reduces the need for additional oils, greases and desiccants

- Vapors penetrate recessed inaccessible areas

- Once unpacked the metals do not require additional cleaning or degreasing treatments

- Numerous benefits result in reduced labor costs

Corrosion

- Corrosion is the deterioration of a material undergoes as a result of its interaction with its surroundings. Although this definition is applicable to any type of material, it is usually reserved for metallic (ferrous and non-ferrous) alloys. Corrosion processes not only influence the chemical properties of a metal but also generate changes in its physical properties and its mechanical behavior.

- Corrosion is the electrochemical reaction between a material, usually a metal, and its environment that produces a deterioration of the material and its properties.

- Corrosion is the oxidation of metals in the presence of water or water vapor etc.

Corrosion results in tarnish, pitting, and flaking

Cost of Corrosion

- A recent estimate of the worldwide direct cost of corrosion – for prevention as well as repair and replacement – exceeded $1.8 trillion.

- India loses $40 billion* a year due to corrosion in infrastructure and industries segments – about 4 % of the size of the total economy *Ref. Press Trust of India New Delhi, Oct 2014

Fighting Corrosion With VCI

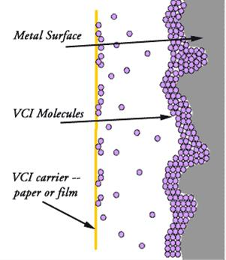

- Vapor Corrosion Inhibitors work by diffusing corrosion inhibiting molecules from a source (packaging film or paper for example) to metal surfaces.

- These molecules settle on metal surfaces and form a protective corrosion inhibiting layer that inhibits the electro-chemical reactions that cause corrosion to form.

- An estimated 25 to 30 % of the annual cost of corrosion can now be avoided if optimum corrosion management practices are employed i.e. VCI packaging. VCI is one of the most cost effective versatile tools fighting corrosion.

How Does VCI Work?

When VCI is incorporated into a polymer system or Kraft paper, the finished product offers corrosion protection by releasing vapors which form a monomolecular protective layer on the surface of the metal component to be protected. This protective layer remains until the package is opened and then evaporates leaving a clean metal surface that is free of corrosion.

VCI Protection is a Function of:

- Which metals are in need of protection?

- Corrosion inhibiting chemicals used and their effectiveness on the metals.

- Ratio of chemicals in the formulation.

- Amount of VCI in the paper or in the film.

- Water solubility and the effectiveness of the corrosion inhibitor in presents of moisture and/or high humidity.

- The overall packaging design and the conditions expected during packaging, shipping and storing.

VCI Applications

Automotive

Defense

Electricals and electronics

Metal Packaging

Author – Mercy P. Bulsari

Polymer Professional

Techno-Commercial Business Development Director

Email: mbulsari@oxobioplast.com

Phone: +1 437 986 1135 (Cell)